sanding...

most of the chair...HOTT.

Weee!!

the big. the bad. the MEGA. architecture as a global condition.

The subways have long been occupying the subterranean spaces of cities, and roads have cut through mountains and cliffs in the form of tunnels. Boston's "Big Dig" is an attempt to drop the major arteries of traffic below the city to expose space for beauty and leisure in place of chaotic traffic.

The subways have long been occupying the subterranean spaces of cities, and roads have cut through mountains and cliffs in the form of tunnels. Boston's "Big Dig" is an attempt to drop the major arteries of traffic below the city to expose space for beauty and leisure in place of chaotic traffic. More important, I think, than the technicalities of what the "Big Dig" project is attempting to accomplish, is what this thinking - traffic below, walking up top - could accomplish if implemented in more cities.

More important, I think, than the technicalities of what the "Big Dig" project is attempting to accomplish, is what this thinking - traffic below, walking up top - could accomplish if implemented in more cities.

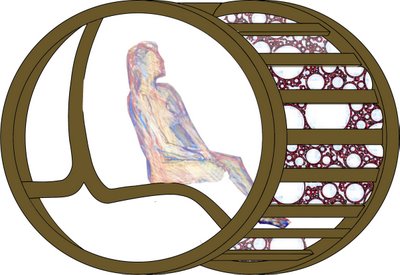

side sections

side sections front elevation with wheel sealed (left)

front elevation with wheel sealed (left)

Sound Absorbing Materials: cork board, carpet, open-celled foam, wood, chair, person, blankets (fiberglass, felt, wood wool), perforated tiles etc., lead

diffuser panel (diffuses sound to prevent interrupting waves)

foam

spray-in open-cell foam insulation

multi-density composite fiber panel

vinyl sound barrier

2. Isolation- isolating the station from other surfaces by using buffering materials will prevent sound from escaping and entering the station

-Rubber or vibration absorbing buffers between structure and ground/floor/walls

-Cavity within walls reduces vibrations (outer wall furred-out)

3. Shape-the shape of the station will determine how the sound is distributed. Because the station will be relatively small, this is not as important of an issue as materials is, but it could inform the design of the structure and overall shape of the station.

-Concave shapes reflect sound back to the source

-A spherical shape, like the egg chair Katy mentioned, will focus the sound to the center and not allow much exterior noise.

-Absorbent material will be necessary regardless of the shape because of the scale of the project.

Here are some proposed methods to controlling the spatial characteristics of sound based on body position and environment. The following are mentioned in Sound:Space by Bernhard Leitner.